What do we need to know about stock management?

Stock management is one of the most challenging areas of integration in general. It appears to be a particularly difficult business operation for tech webshops and websites offering FMCG goods. But before we look further into this, let’s clarify what we mean by stock management automation in general. See a few examples below:

- One of the most common problems is when the online and offline platforms of a business merge and start trading as one. In such cases the webshops don’t tend to have a dedicated stock of their own, meaning that they sell the same stock online that’s being allocated to physical stores. Real-time stock updating is essential for businesses following this pattern.

- Another standard practice is selling the same products and the same stock on multiple online platforms at once. What seems to cause issues here is when the last item is being sold to different customers via different platforms at the same time. If the stock information is not being refreshed quick enough, you’d might as well choose to sell on one platform only instead.

- Being somewhat similar to the above, sometimes one webshop manages multiple stocks at once. A perfect example of this would be a multibrand webshop that needs to aggregate the different stock information of different retailers at the same time.

- If online orders can be picked up in store, automated stock updating is of the essence. Users must be able to see which products are available where and once they placed their orders, the items must automatically be secured for them from the store’s stock.

- Showing the suppliers’ stock levels on our website – besides our own – can be a great solution sometimes. One thing to bear in mind though in such case is that the users might expect delivery times longer than usual. These operations are also part of an integration process during which our webshop gains access to the suppliers stock information to synch it with our own records.

- Products with expiry dates can be arranged and sorted within the stock so that the one that goes off earliest will be sold first.

- Automation also allows stock information of unique products to be managed easily. Such items might include used goods: second-hand books or outlet and used garments for example. Each of these products might have their own prices, descriptions, and photos – this can mean that even the exact same items might have completely different product attributes. There is a technical solution to overcome this issue though: generic attributes can be created for one hero product, to which all items of the same kind can be attributed to, each carrying their own product ID. Once this is done further information can be added to the ‘sub-products’ such as condition, availability and unique product pictures can also be uploaded to each.

What do the numbers say?

The stock information listed above is not only relevant to big retailers with multiple stores and online outlets. Based on a number of case studies on shopping behaviours, nChannel points out the most important aspects of real-time stock management:

- 58% of online customers thought that it was important to have the stock information of a product displayed on the retailer’s website.

- 41% of customers abandoned their carts at the checkout when they found out that the item(s) they were planning to buy were not available.

- 38% of customers prefer online stores over traditional ones, because they can access stock information more easily.

- And last but not least, let’s not forget about orders that can’t be fulfilled because of a stock overrun. These create bad customer experiences and they also add unnecessary workload to the administrators, to customer service and to the accounting departments.

When does automation become absolutely necessary?

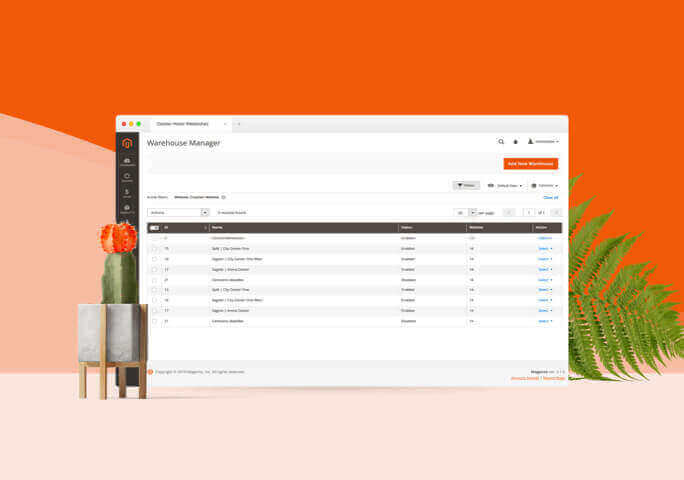

Most webshops already have built-in stock management functionalities but these only stretch to a certain extent. The automation of stock management and the integration that comes with it will be more relevant and important if you have an existing ERP or another logistical software – either one being the main platform where stock information is managed. Let’s see why:

- Orders placed in the webshop will need to appear in the ERP immediately so that stock levels are reduced accordingly.

- Similarly, stock changes in the ERP should appear in the webshop just as quickly (to ensure accurate stock information to customers and to avoid stock overrun for orders).

- Stock movement data should be interchanged between the webshop and the ERP so that the information matches up on both platforms.

- Synching should ideally be two-folded, meaning that both systems can share information with the other.

After a while, the implementation of automation processes will become unavoidable. Let’s see the possible options.

What technical solutions are there for automation?

By default, synching can be scheduled, meaning that the stock information is updated every few minutes between the system. This solution however might leave room for some errors. Just think about a Black Friday campaign period for example, during which you might have a high amount of orders being placed within a short period of time. This could easily result in overruns that would have a negative effect on the customers’ shopping experience.

NChannel’s study also points out, that real-time stock management doesn’t mean that you would refresh your data every 15 minutes, every hour or once a day only. If you risk doing so, you might end up showcasing inadequate stock information on your channels. Stock overruns might happen more often if you don’t keep information fully updated quick enough. What’s more you can’t present up-to-date stock levels to your customers either if the data is not managed properly.

The alternative solution – which is event driven – is more error resistant. This ideally means that if stock levels change in one system, the data is immediately updated in the other as well. To achieve a more efficient level of stock management, real-time synching is needed. This makes it possible to reduce stock levels across all channels once an order is placed and this is the only way to showcase accurate stock information to the customer on our platform.

Planning the stock automation process

There are reasons why we mentioned earlier that integration is one of the most crucial aspects of stock management when it comes to ecommerce projects. There are a series of questions that need to be answered, that we need to think about if we are planning to integrate our webshop with our ERP. Here are a few of these for reference:

- Do we have a dedicated stock or are we selling the stock of our offline store(s)? Or is it maybe a combination of both?

- How does the information about stock levels reach the webshop?

- How do order-generated stock level reductions reach the ERP/external stock management system(s)?

- How often does the stock change?

- Would unavailable items be de-published from the site or would they just appear to be unshoppable?

- What kind of stock statuses are we planning for? Would these influence delivery times, available shipping options or payment methods? If so, how?

- How, at which point and how prominently would we like to showcase stock information?

- Would we like to add catalogue filters, sorting and navigational tools to the stock attributes?

- Is there a possibility to integrate the suppliers stock information? Do we have access to these or are these being sent to us? What kind of data are we receiving and in what structure? How accurate and up-to-date are these information?

Of course, based on our industry and our market several other specific questions might come up, so it’s worth taking the planning seriously by answering as many of these questions as possible.

How can stock synching automation support the operations of our webshop?

Here’s a brief list of common requests and functionalities to consider:

- An event-driven operation is key so that stock information is fully up to date both in the webshop and in the ERP.

- Pausing stock level data of new items. If new stock is delivered before the items being uploaded to the website from the ERP, it will be on hold. The process will be paused until the product attributes are being assigned to the items – once this is done, stock levels will be updated automatically as well.

- Calculations of stock availability. The data package we receive features two values: one showing the entire stock availability of the product and the other showing the booked/ordered amount. If we deduct the booked amount from the complete stock, we will see the value of the available stock remaining.

- Setting product statuses. Based on business logics we can decide whether a product could still be available to purchase after selling out our own, booked stock or not.

What does the speed of stock automation depend on?

As we explained above, automation itself is not enough if it works slowly and if it only updates our stock information once a day. Time and speed are of the essence, especially during a dedicated campaign or promotion period.

How fast could stock automation be?

By default, the speed of the synching process within the integration depends on the following things: the available resources and the current load of the sender (usually the ERP), the middleware and the receiver (webshop). Based on experience, even in the worst cases the whole process should be turned around in a few seconds when it comes to event-led synching. If the synching is scheduled, the turnaround and the speed of the process depend on the time-slots that are set in advance.

Why is it worth working with a middleware when it comes to stock automation?

Implementing a middleware solution can be a great option if we would like to manage large amounts of data in an even-led system: in such a case stock information changes need to be instant and we have existing business logic being attributed to the process as well (integration with other CRM or ERP systems).

So far, we’ve discussed the synching processes of ever-changing stock information but let’s not forget about the products themselves, their prices and price lists, and customer and order data. Stay tuned and find out more about these in our next article.

The original Hungarian version of this article was published on Kosárérték.hu. This piece was written by our colleague Dávid Roskó, who has been the Integration Business Leader of OANDER Development Ltd. since 2016.